Overview

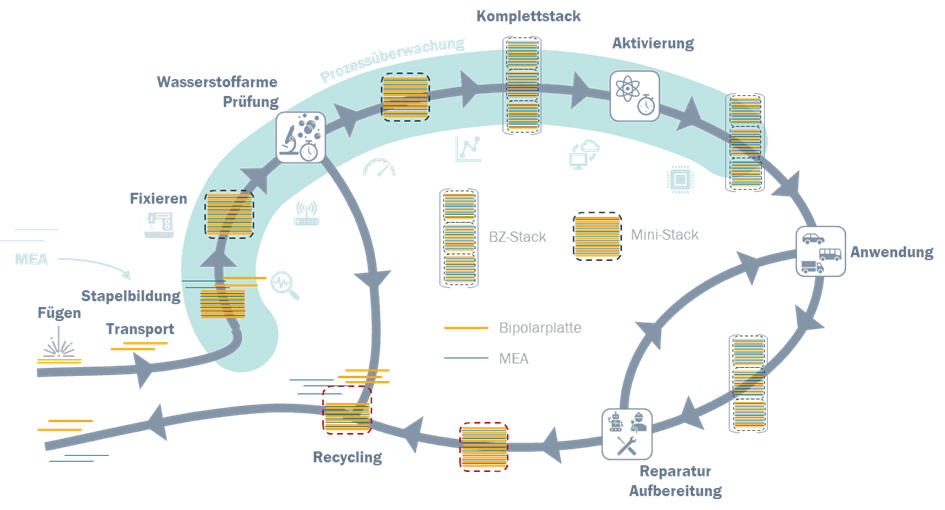

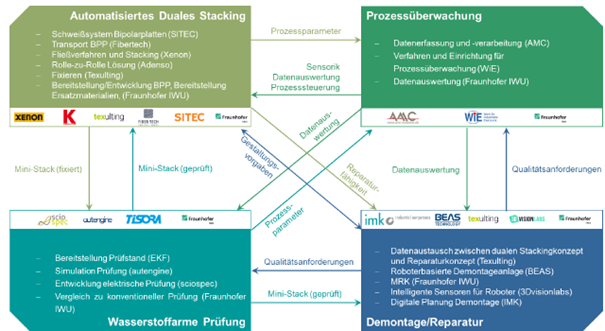

Overall project: Realization of a high-rate capable stacking process with the four sub-projects automated dual stacking, process monitoring, low-hydrogen testing and disassembly and repair of stacks.

Subproject imk (TP11): Digital planning of scalable hybrid disassembly workstations Design and development of planning methods for the (semi-)automatic planning and adaptation of the disassembly of stacks and their implementation in a software demonstrator (ema disassembly & ema MRK module).

Grantor:

RUBIN - Regional Entrepreneurial Alliances for Innovation, funded by the BMBF

Funding code:

03RU2U021K

Term:

01.08.2023 - 31.07.2026

Project content

"DuSwaP" is a regional entrepreneurial alliance for the development of value chains for the production of fuel cells (FC) in Saxony. The vision is to use DuSwaP and the 14 partners clustered in it to develop innovative manufacturing and production solutions at several points along the value chain in FC stack production, ranging from automated dual stacking, process monitoring and low-hydrogen testing to the dismantling and repair of stacks.

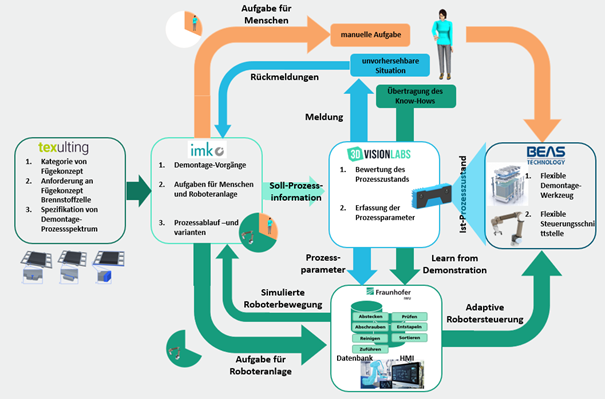

The aim of DuSwaP is to realize a high-rate capable stacking process. To this end, the sub-project Dismantling & Repair (partners: IWU, BEAS, 3D Vision Lab, imk) deals with the repair and dismantling of non-functional or old fuel cell stacks in the overall view in order to realize a sustainable and economical product life cycle. The aim is to find a generally applicable, machine-compatible solution that can efficiently and cost-effectively repair faulty fuel cell stacks or completely dismantle them at the end of their life and return them to the material cycle. In addition to these premises, the planning and subsequent realization of the dismantling area and the associated workstations must ensure an economical, ergonomic design and take into account changing quantities during the market and life cycle.

Research focus imk

In sub-project TP 11, Imk is working on the design and development of planning methods for the (semi-)automatic planning and adaptation of the disassembly of stacks and their implementation in a software demonstrator (ema disassembly & ema HRC module). The ema disassembly and HRC module is intended to enable scalable planning of hybrid workplaces, i.e. under direct, time and task-oriented human-robot interaction / collaboration (HRC), taking unplanned situations into account. Unplanned situations are, on the one hand, product and production states that do not correspond to the normal state or are not expected by the worker but have already been pre-planned by the system and, on the other hand, unforeseeable states that have not been planned by either the worker or the planning tool. For both cases, the planner and the worker should be provided with adequate execution suggestions and assistance.