Overview

Development of a method for the integrated planning and realization of collaborative workplace systems in assembly with variable product scenarios. Innovations for the production, service and work of tomorrow

Grantor:

Federal Ministry of Education and Research (BMBF)

Funding code:

02P15A060

Grant Program:

Innovations for the production, service and work of tomorrow

Term:

01.01.2017 - 31.12.2019

Project Sponsor:

Project Management Agency Karlsruhe (PTKA)

Project objective and approach

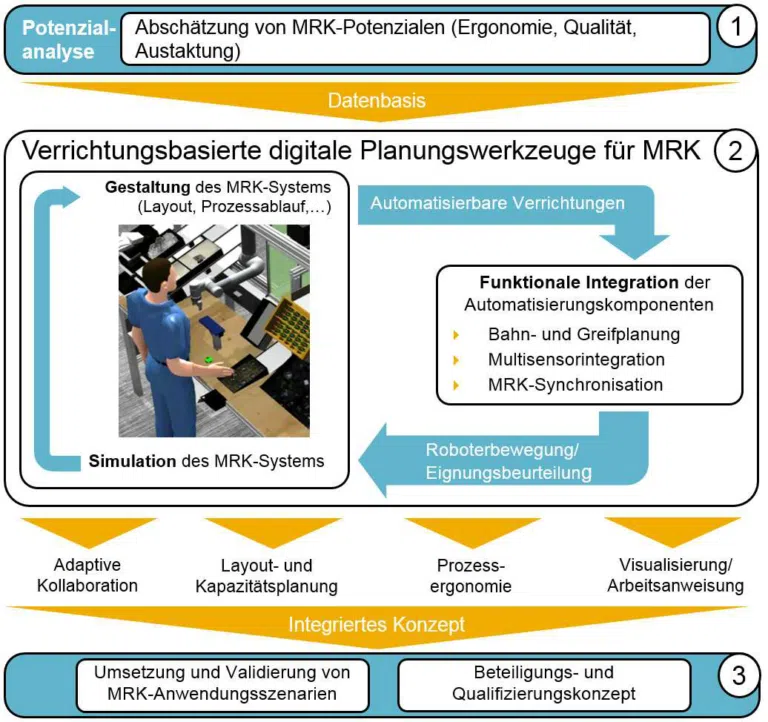

The aim of the KoMPI research project is to develop a new method for the integrated planning and realization of collaborative workplace systems in assembly for variable product scenarios, which will enable small and medium-sized enterprises (SMEs) in particular to plan and deploy MRK systems.

Pilot testing at the participating industrial partners will validate the diverse components to be developed for the design and integration of MRK during the project.

Main focus of imk automotive GmbH

Up to now, two parallel planning worlds exist in which the processes for robots and humans can be modeled, simulated and evaluated separately with different emphasis. For the planning of work systems for human-robot collaboration, it is necessary to extend the simulation of human work, which is currently the core competence of imk, to include robot simulation. An essential aspect is the conception of an overall architecture of the integrated planning solution with the essential system components.

Based on the philosophy of the process language for manual activities with stored fixture libraries, adequate robot-based fixture modules are to be derived. The functional integration of the system components into the planning tool creates the possibility to plan collaborative assembly systems early and effectively and to secure them by means of a simulation before the actual implementation. In particular, the interaction of both actors must be represented realistically in order to achieve a high level of acceptance, for example, in the communication of the planning projects to employees and the works council.

Furthermore, evaluation options must be integrated that provide information about the efficiency, ergonomics and safety of the designed MRK working systems. An important key is the development of open interfaces to existing systems for the seamless import and export of data.

Project partner

Downloads & further links

- ZWF - Zeitschrift für wirtschaftlichen Fabrikbetrieb - 11/2019: Simulation-supported occupational science evaluation of MRK workplaces.

- Practice-oriented information on human-robot collaboration based on recent research results

- 06/2018: Wholistic Human Robot Simulation for Efficient Planning of HRC Workstations, ERCIM NEWS No. 114.

- 06/2018: Development of a sociotechnical planning system for human-robot interaction in assembly systems focusing on small and medium-sized enterprises, CIRP Manufacturing Systems Conference 2019.

- To the official KoMPI website