Overview

Investigation of human motion variance for the validation of MRK processes in the planning simulation incl. implementation of the motion variances in the planning tool ema

Grantor:

Saxon Development Bank (SAB)

Funding code:

100376593

Term:

08.10.2020 – 07.10.2022

Project content

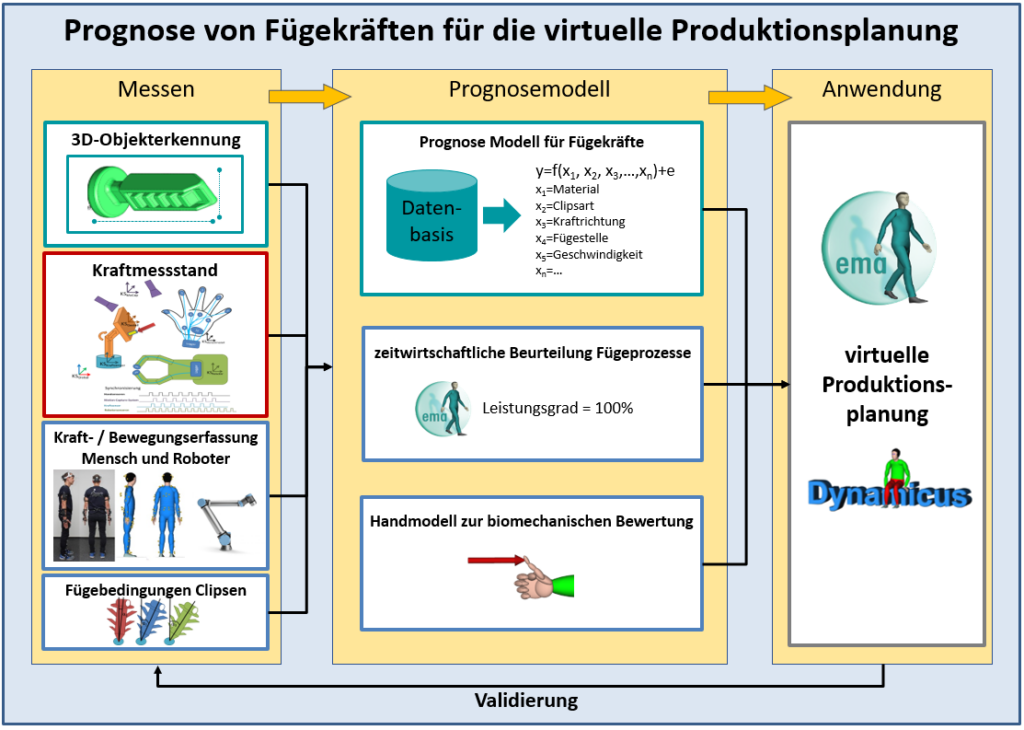

The assembly of automobiles, electrical or even household appliances requires many manual assembly steps. There has been a sharp increase in the use of clips and plug-in connections. Since the manual work processes often have to be carried out at high frequency with simultaneous joining forces, there are high stresses on the hand-arm system, which can promote the development of musculoskeletal disorders such as tendovaginitis if they are not carried out ergonomically or if the design of the joining elements is unfavorable.

For the ergonomic and economic evaluation in ema, currently necessary joining forces have to be entered manually on the basis of estimates, measurements or FEM simulations (finite element method). On the one hand, this requires a great deal of effort and, on the other hand, can lead to the aforementioned overstressing of people if the estimated values are incorrect. For this reason, a methodology for the valid and efficient determination of joining forces and times on the basis of numerical calculation functions for ergonomic force evaluation (assessment) and evaluation of economic efficiency in virtual production planning is being developed as part of the research project 'SimKra', and the effects on the hand-arm system are being determined.

The task of imk Industrial Intelligence GmbH in the project is the development of a numerical model for the prediction of joining forces depending on the joining conditions and their prototypical integration into the ema Work Designer. The basis of the methodological development is formed by extensive series of measurements, which are carried out on a newly developed adaptive and modular force measuring stand, as well as FEM simulations.

For the application of the prognosis model in the ema, software methods for the recognition and classification of relevant influencing variables of the joining process, e.g. geometric information on the joining point and on the joining elements for the determination and evaluation of the joining force, are also being developed, and the ergonomic evaluation is being extended in order to be able to evaluate hazards for the hand-arm system.

With the help of the ema Work Designer digital planning tool, manual or partially automated work processes can be simulated early in the planning phase and evaluated and designed according to ergonomic, economic and safety criteria. The joining forces required for ergonomic evaluation currently have to be entered manually on the basis of estimates, measurements or FEM simulations (finite element method). On the one hand, this requires greater effort and, if the estimated values are incorrect, can lead to the aforementioned overstressing of people.

Research focus

- modular force measuring stand

- Numerical model for predicting joining forces as a function of joining conditions

- Simulation model for the hand-arm system

- Methodology for biomechanical and temporal evaluation of joining forces

Derivation of relevant influencing variables from ema for joining force simulation (e.g. object recognition, fit classes) - Guideline for the determination of joining forces incl. measuring instructions especially for the application in SMEs

Project partner