Design and implementation of 1,200 insertion force measurements of joining forces for BSH Hausgeräte GmbH.

Customer benefits:

Complete and methodical analysis of the work system in the Wendt & Kühn painting shop and elaboration of measures to optimize work organization and work design for more health, productivity as well as motivation of employees and managers.

Customer benefits:

Analysis and simulation for process optimization at the motor home and caravan manufacturer CAPRON, among other things, through measures such as no bending due to optimized working heights, better posture or reduced walking distances for load handling.

Results:

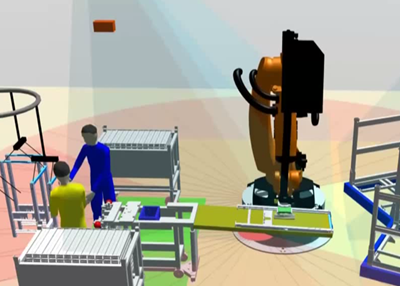

Development of different process variants for assembly as well as planning of human-robot collaboration in ema to improve productivity, ergonomics and utilization.

Results:

"With the ema Work Designer, we are able to check the plausibility of assembly processes with regard to F-time and ergonomics. Another significant advantage for process planning is the possibility to consider employees with activity restrictions at an early stage. The visualization of work processes also provides us with a very good discussion basis for cycle time discussions and 3P workshops."

Dr. Ricardo Schönherr

Production System Manager/ Projects (TIP) I Industrial Engineering/ Production System (TI)

Volkswagen Saxony GmbH

"The ema Work Designer enables us to build up a complete assembly digitally. In this way, we create a better basis for planning and develop a common understanding of the process and equipment with the customer at an early stage. The software makes it possible to safeguard up to 90% manual activities in assembly and, in our view, makes a very valuable contribution to the digitalization of assembly planning. Compared to other solutions, ema thus has a unique selling point."

Torben Möller

Head of Assembly Planning / Head of Planning Smart Factory North

EDAG Production Solutions GmbH & Co. KG

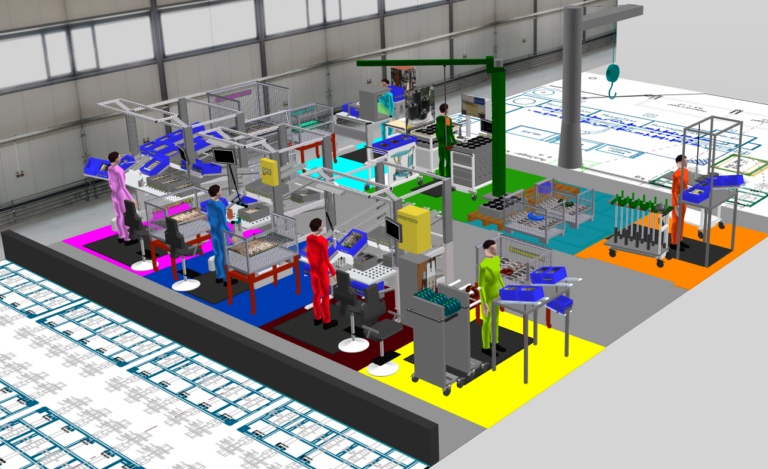

Planning of a central production area and virtual workplace design for the value-added integration of employees with limitations in production.

Results:

imk Industrial Intelligence GmbH

Amselgrund 30

09128 Chemnitz