Task

Implementation

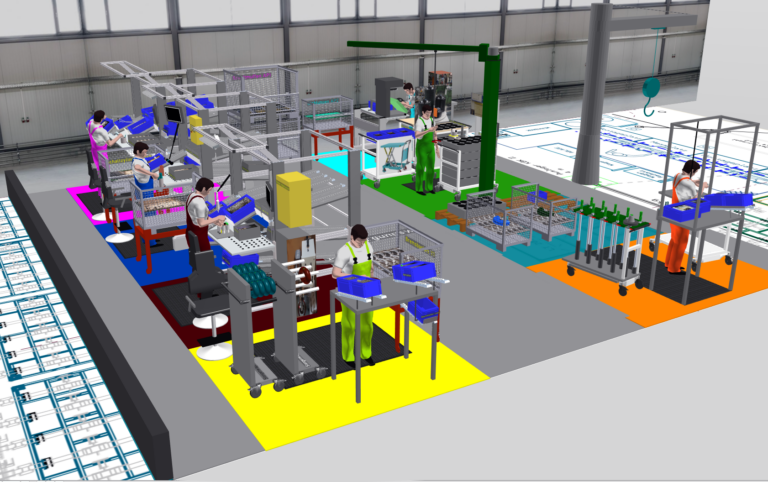

In the first step, the current actual conditions including all necessary data were recorded in an on-site inspection. In addition to information on the required components (e.g. weights, material requirements and daily requirements), this also included the dimensions and functions of the devices used at the workstations. On this basis, the ema Work Designer software solution was then used to create an initial digital layout concept for mapping the necessary material supply, equipment and basic workplace dimensions, taking into account current guidelines.

The next step was the iterative detailing of the initial scenario according to the requirements of capability-oriented workplaces. This included not only the adaptation of the material flow (e.g. reduction of the load handling of KLT/GLT) but also the technical redesign of e.g. fixtures and manipulators. While ensuring ergonomically favorable work processes, the assembly volumes at the individual workplaces were then simulated and further potential for improvement was identified. The iterative optimization of the individual workstations was carried out in a continuous exchange of ideas, including workshops with planning, production and logistics on site.

Based on the coordinated solution as a digital simulation, technical specifications were created for each workstation. This was followed by the first assembly of the workstations in the prototype workshop.